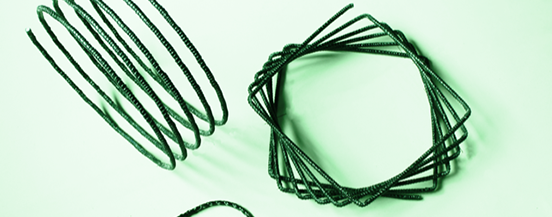

FRP Bars for Concrete Reinforcement

FRP bars are made from composite materials (Fiberglass, Carbon Fiber or Basalt Fiber) and manufactured by a pultrusion process using a mix of recycled fibers and resin with various additives.

manufactured by a pultrusion process using a mix of recycled fibers and resin with various additives.

FRP bar was developed as a non-corrosive, more sustainable, alternative to steel for concrete reinforcement. It is suitable for any structural or architectural concrete-based application where a material that is corrosion resistant, lightweight, or non-conductive is required.

Milltrade supports and distributes SFT-Bar®, supplied and manufactured by SFTec, Inc.

Benefits of FRP Bars

FRP reinforced concrete infrastructure projects have several benefits thanks to its properties:

- Lightweight

- Non-Corrosive

- Unsusceptible to Chemical spills

- Long-term durability

- Competitive cost and energy efficiency

- Improves installation work efficiency

- Totally unaffected by chloride ions

- High tensile strength

... and so much more!

Contact us

Applications of FRP Bars

FRP bar is the ideal solution for concrete reinforced projects, such as:

- Bridges, Barriers walls and decks

- Pavements, multi-storey parking garages, roads, balconies, etc.

- Diaphragm wall (soft eye), foundation pit retaining piles

- Precast Tunnel Segments

- Mining roadway support and tunnels with Rock bolts

- Wharfs, sea walls, wave breaker, water treatment plants